Detail engineering

Detailed Engineering: Precision at Every Stage

HighTec Energy offers comprehensive detailed engineering

services, translating conceptual designs into actionable plans

with meticulous attention to detail, ensuring project success

and operational excellence.Ex

Our Approach to Engineering Excellence

At HighTec Energy, Detailed Engineering is the backbone of successful project execution. We transform

initial concepts into fully realized, constructible designs, meticulously addressing every technical

specification, regulatory compliance, and operational requirement. Our seasoned engineers leverage

cutting-edge tools and a rigorous methodology to deliver designs that are not only innovative but also

practical, cost-effective, and built to last. We focus on delivering robust solutions that stand the test of

time, ensuring peak performance and reliability.

Key Benefits of Partnering with HighTec Energy

Conceptual

- Growth Opportunities and Fundamentals Research.

Front End Engineering Design (FEED)

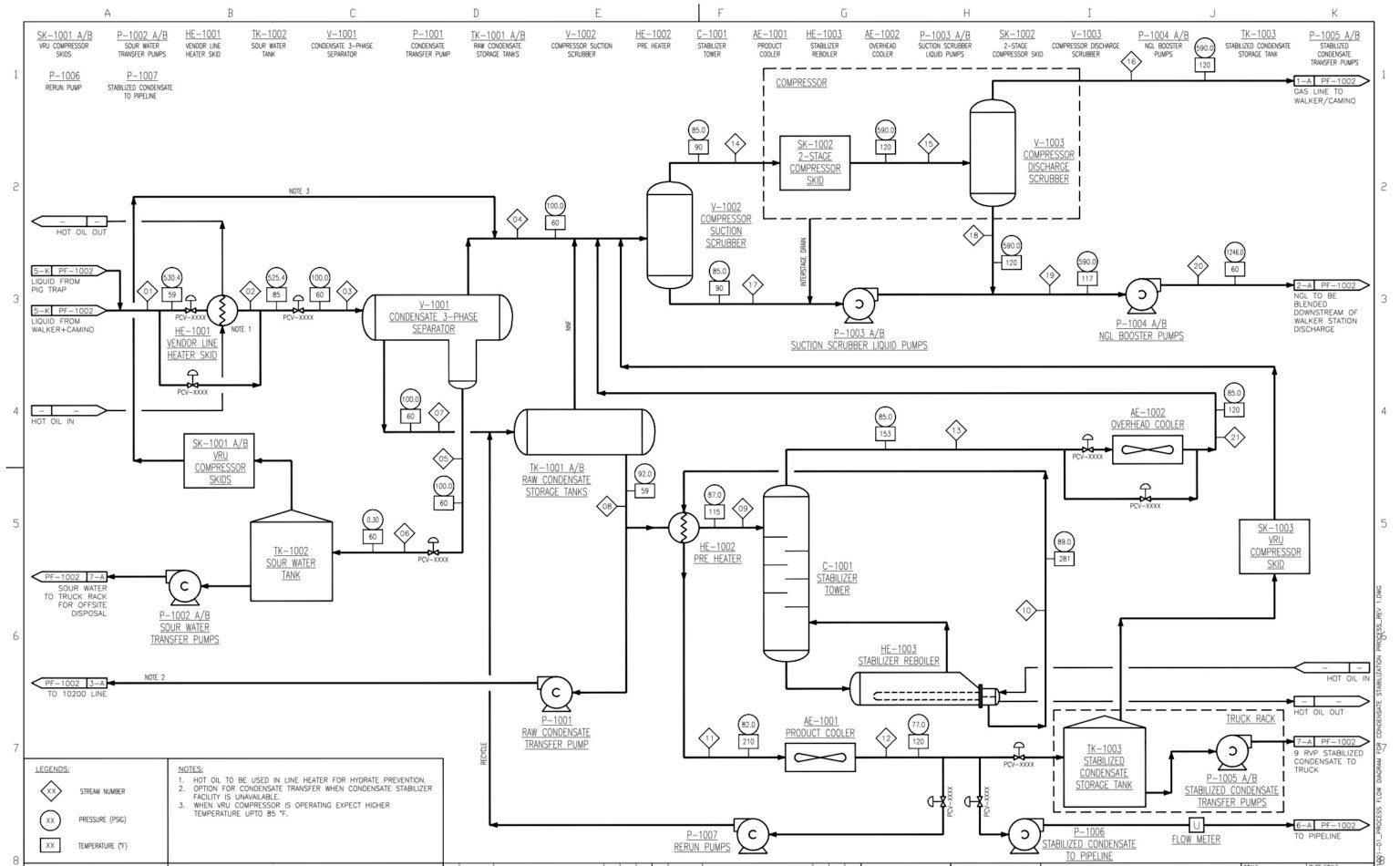

- PFDs.

- One Line Diagrams.

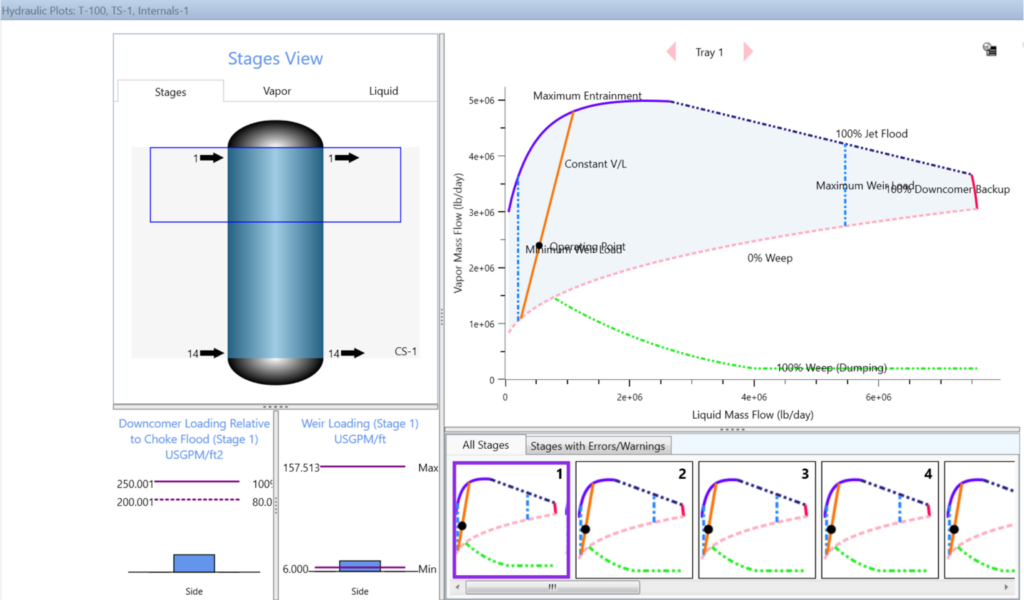

- Hydraulic Modeling.

Detail Engineering & Construction Support

- Detailed 3D Pipe Modeling.

- Dispersion Studies.

- Equipment Rating & Design.

- Terminal Design.

Commissioning

- HAZOP.

- What-if Analysis.

- FMEA.

-Flow Rates off PI Data Sheets.

Operations & Optimization

- Technical Training.

- Process Revalidation.

CFD Wall Temperature Analysis

Process Flow Diagram for Stabilization Units

Terminal Block Design

Vapor-Liquid Equilibrium Curve for Composition

Process Simualtion for Amine Contractor

3D Pipe Model